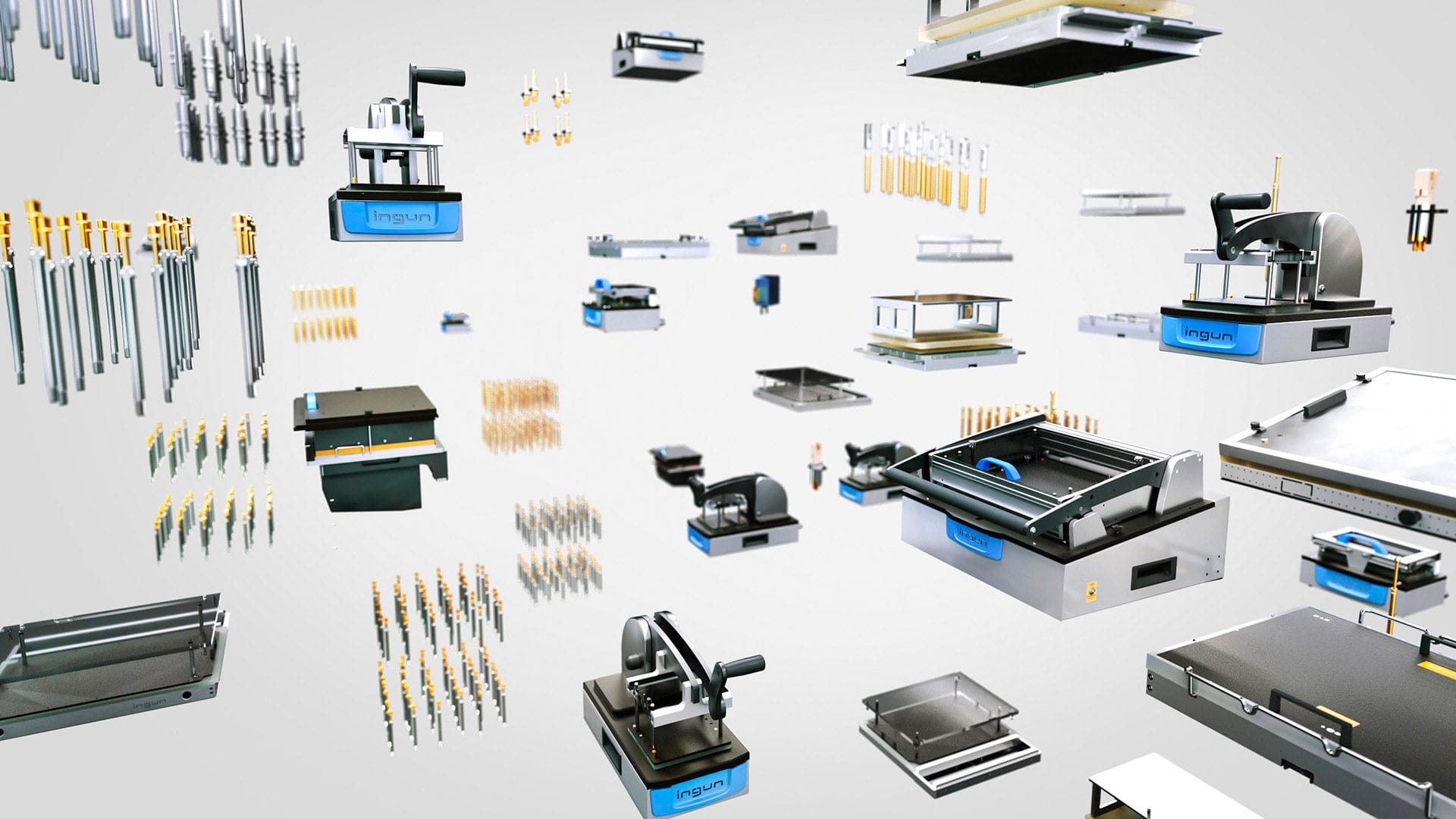

Produkte

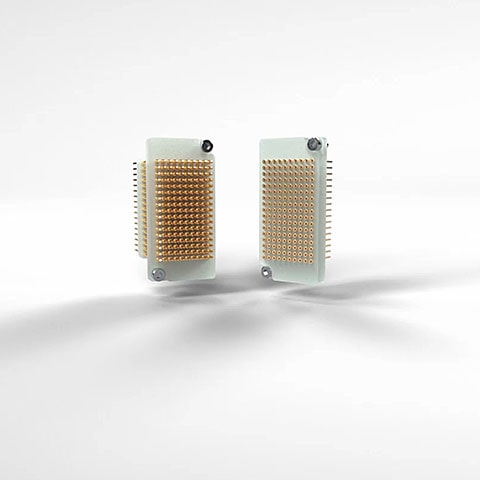

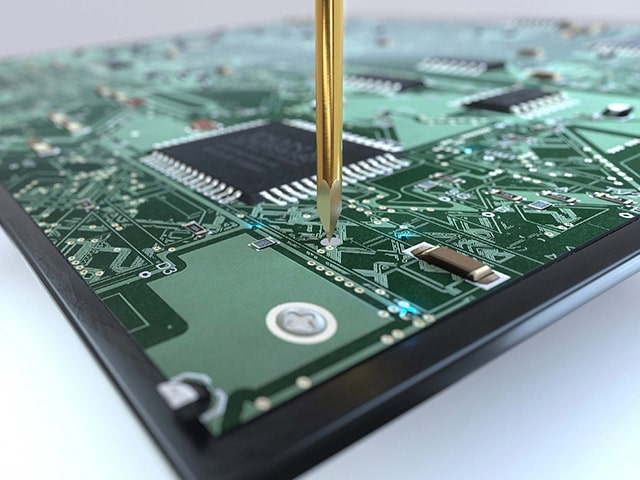

Für einen zuverlässigen Kontakt zwischen Testpunkt und Testsystem.

Partner für die Technologie der Zukunft

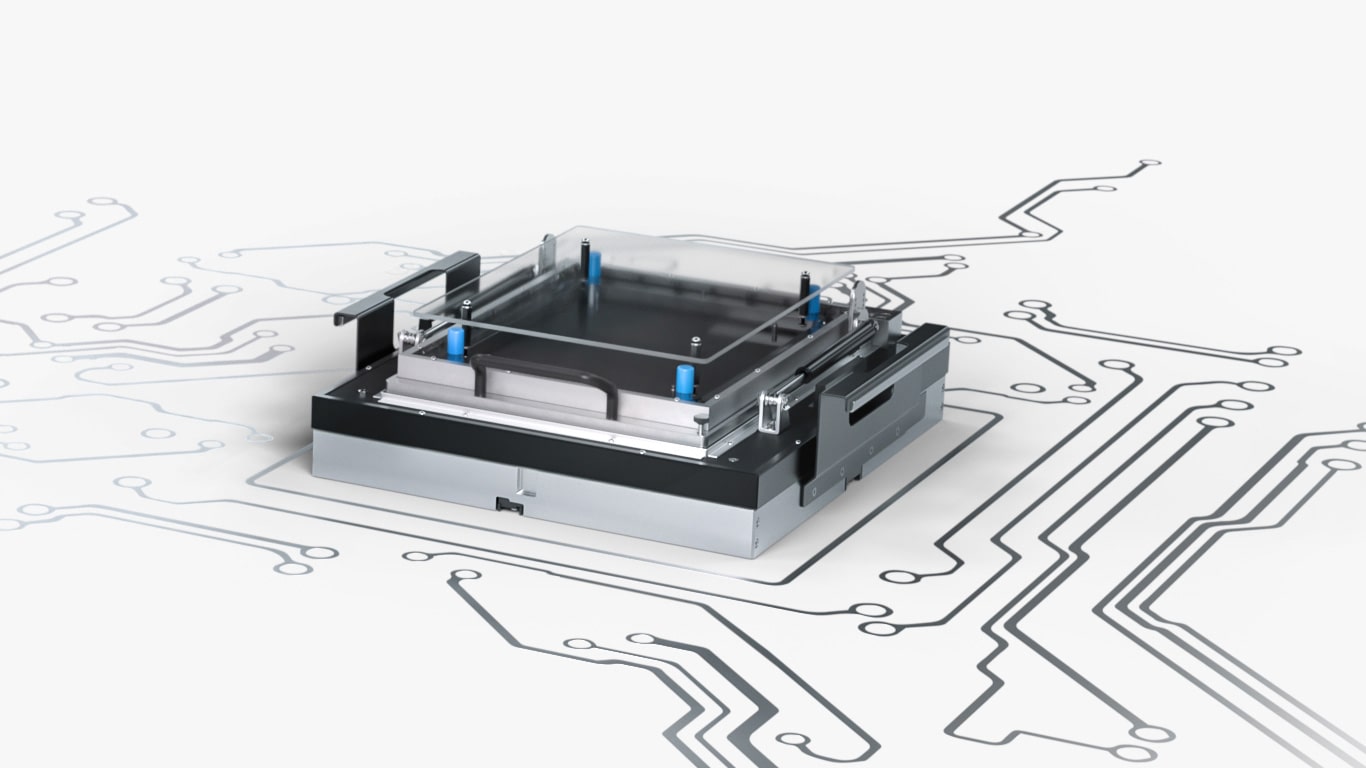

Innovative Prüftechnik -

überall einsetzbar.

Prüflösungen für die Automobilindustrie und Zulieferer

Kontaktierlösungen für eine stabile Kommunikation und sichere Datenübertragung

Allerhöchste Qualität von Prüfmitteln in der Medizintechnik

Leistungsstarke Prüftechnik für die Energiewende

Aerospace Lösungen für höchste technologische Prüfanforderungen

Aktuelles

Neuprodukt-Highlights, News, Termine und Themen aus unserem TechTalk.

INGUN Prüfmittel - "Made in Germany".

In einer dynamischen, hochgradig vernetzten Welt ist es gut, wenn man sich auf jemanden verlassen kann. Deshalb entwickeln wir von INGUN leistungsfähige Prüftechnik für elektrische und elektronische Komponenten. Mit einem unübertroffenen Sortiment sind wir global präsent. Unsere Lösungen verleihen elektronischen Erzeugnissen erst jene Qualität und Verlässlichkeit, ohne die sie nicht funktionsfähig wären. Für unsere Kunden sind wir Entwicklungspartner für Innovationen und setzen auf höchste Qualitätsstandards "Made in Germany".